SPX1117T-L Просмотр технического описания (PDF) - Exar Corporation

Номер в каталоге

Компоненты Описание

Список матч

SPX1117T-L Datasheet PDF : 11 Pages

| |||

SPX1117

800mA Low Dropout Voltage Regulator

APPLICATION INFORMATION

OUTPUT CAPACITOR

To ensure the stability of the SPX1117, an

output capacitor of at least 2.2µF (tantalum or

ceramic) or 10µF (aluminum) is required. The

value may change based on the application

requirements of the output load or

temperature range. The value of ESR can vary

based on the type of capacitor used in the

applications to guarantee stability. The

recommended value for ESR is 0.5Ωor less. A

larger value of output capacitance (up to

100µF) can improve the load transient

response.

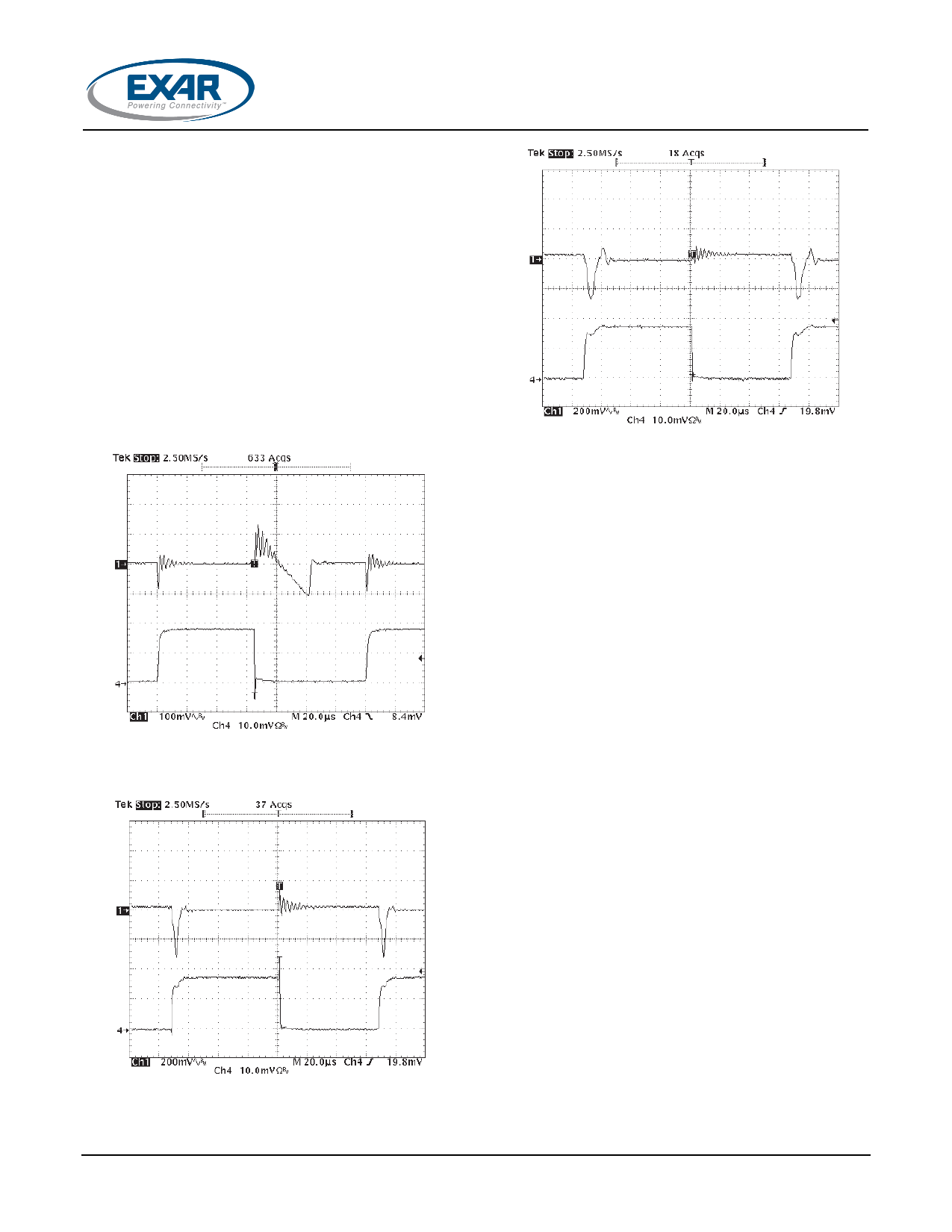

Fig. 18

Fig. 16: Load Step Response 0mA to 800mA

VIN=3.3V, VOUT=1.8V, CIN=10µF, COUT=2.2µF, Ceramic

Signal 1=VOUT, Signal 4=ILOAD

SOLDERING METHODS

The SPX1117 SOT-223 package is designed to

be compatible with infrared reflow or vapor-

phase reflow soldering techniques. During

soldering, the non-active or mildly active

fluxes may be used. The SPX1117 die is

attached to the heatsink lead which exits

opposite the input, output, and ground pins.

Hand soldering and wave soldering should be

avoided since these methods can cause

damage to the device with excessive thermal

gradients on the package. The SOT-223

recommended soldering method are as

follows: vapor phase reflow and infrared

reflow with the component preheated to within

65C of the soldering temperature range.

Fig. 17: Load Step Response 0mA to 800mA

VIN=3.3V, VOUT=1.8V, CIN=10µF, COUT=2.2µF, OSCON

Signal 1=VOUT, Signal 4=ILOAD

© 2011 Exar Corporation

THERMAL CHARACTERISTICS

The thermal resistance of SPX1117 (SOT-223

package) is 15°C/W from junction to tab and

31°C/W from tab to ambient for a total of 46

°C/W from junction to ambient (Table 1). The

SPX1117 features the internal thermal limiting

to protect the device during overload

conditions. Special care needs to be taken

during continuous load conditions such that

the maximum junction temperature does not

exceed 125 °C. Thermal protection is activated

at >155°C and deactivated at <140 °C.

Taking the FR-4 printed circuit board and 1/16

thick with 1 ounce copper foil as an

experiment (fig.19), the PCB material is

effective at transmitting heat with the tab

attached to the pad area and a ground plane

6/11

Rev. 2.1.0