MPX2100 Просмотр технического описания (PDF) - Freescale Semiconductor

Номер в каталоге

Компоненты Описание

Список матч

MPX2100

MPX2100 Datasheet PDF : 8 Pages

| |||

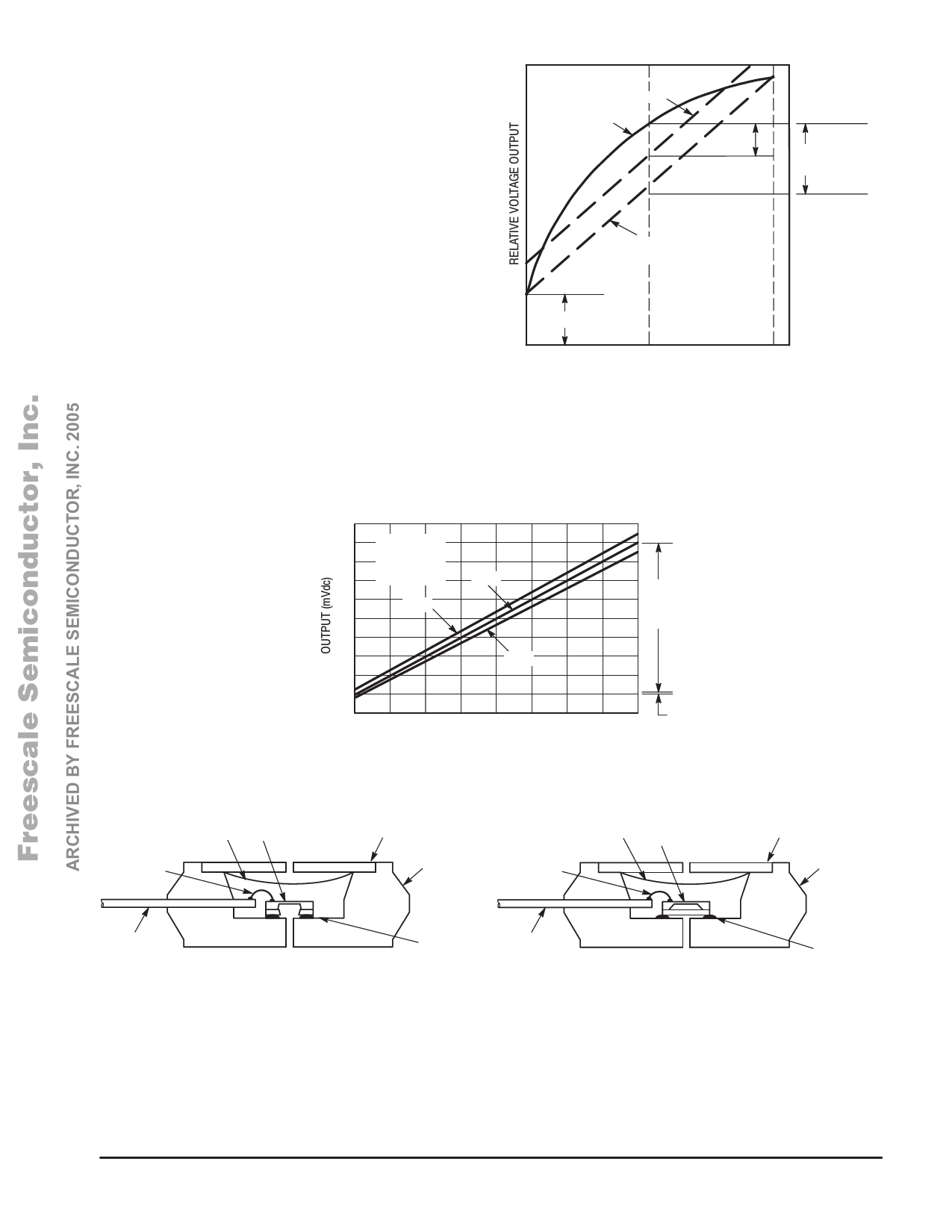

LINEARITY

Freescale Semiconductor, Inc.

MPX2100 SERIES

ARCHIVED BY FREESCALE SEMICONDUCTOR, INC. 2005

Linearity refers to how well a transducer’s output follows

the equation: Vout = Voff + sensitivity x P over the operating

pressure range. There are two basic methods for calculating

nonlinearity: (1) end point straight line fit (see Figure 2) or (2)

a least squares best line fit. While a least squares fit gives

the “best case” linearity error (lower numerical value), the

calculations required are burdensome.

LEAST SQUARES FIT

EXAGGERATED

PERFORMANCE

CURVE

LEAST

SQUARE

DEVIATION

STRAIGHT LINE

DEVIATION

Conversely, an end point fit will give the “worst case” error

(often more desirable in error budget calculations) and the

calculations are more straightforward for the user. Motorola’s

END POINT

specified pressure sensor linearities are based on the end

STRAIGHT LINE FIT

point straight line method measured at the midrange

pressure.

OFFSET

0

50

100

PRESSURE (% FULLSCALE)

Figure 2. Linearity Specification Comparison

ON–CHIP TEMPERATURE COMPENSATION and CALIBRATION

Figure 3 shows the output characteristics of the MPX2100

series at 25°C. The output is directly proportional to the

differential pressure and is essentially a straight line.

The effects of temperature on Full Scale Span and Offset

are very small and are shown under Operating Characteris-

tics.

40

35

30

25

20

15

10

5

0

kPa -ā5 0

PSI

VS = 10 Vdc

TA = 25°C

P1 > P2

MAX

25

3.62

TYP

MIN

50

75

7.25

10.87

SPAN

RANGE

(TYP)

OFFSET

100

(TYP)

14.5

Figure 3. Output versus Pressure Differential

SILICONE GEL

DIE COAT

DIFFERENTIAL/GAUGE

DIE

STAINLESS STEEL

METAL COVER

P1

WIRE BOND

EPOXY

CASE

ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ LEAD FRAME

DIFFERENTIAL/GAUGE ELEMENT

DIE

BOND

P2

SILICONE GEL

DIE COAT

ABSOLUTE

DIE

STAINLESS STEEL

METAL COVER

WIRE

LEAD

BFORANÉÉÉÉMDE ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉPÉÉÉÉ1 ÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉÉ

EPOXY

CASE

DIE

ABSOLUTE ELEMENT

BOND

P2

Figure 4. Cross–Sectional Diagrams (Not to Scale)

Figure 4 illustrates the absolute sensing configuration

(right) and the differential or gauge configuration in the basic

chip carrier (Case 344). A silicone gel isolates the die surface

and wire bonds from the environment, while allowing the

pressure signal to be transmitted to the silicon diaphragm.

The MPX2100 series pressure sensor operating charac-

teristics and internal reliability and qualification tests are

based on use of dry air as the pressure media. Media other

than dry air may have adverse effects on sensor perfor-

mance and long term reliability. Contact the factory for in-

formation regarding media compatibility in your application.

Motorola Sensor Device Data For More Information On This Product,

3

Go to: www.freescale.com