GA355DR7GC101KY02L Просмотр технического описания (PDF) - Murata Manufacturing

Номер в каталоге

Компоненты Описание

Список матч

GA355DR7GC101KY02L Datasheet PDF : 5 Pages

| |||

!Note •PPleleaasseerreeaaddrraatitninggaanndd!!CCAAUUTTIOIONN((foforrsstotorraaggee,,ooppeerraatitningg,,rraatitningg,,ssooldldeerriningg,,mmoouunntitninggaannddhhaannddlilningg))ininththisisPcDatFalcoagtatolopgrteovepnretvsemnot ksimngokaindg/oarndb/uorrnbinugr,neintgc., etc.

C02E10.pdf 04.1.20

•TThhisisccaatatalologghhaassoonnlylytytyppiciacal sl pspeecicficfiactaiotinosn.sTbheecraeufosree,thyeorueaisrenroeqsupeascteedfotrodaeptapirloevdesopuercpifircoadtuiocnt ss.pTehceifirceafotioren,spoleratosetranpsparocvt ethoeuarppprroodvuacl tsshpeeectifoicraptiroondsucotrstrpaencsifaiccatitohnesabpepfororevaolrsdheerientgf.or product specifications before ordering.

GA3 Series Specifications and Test Methods

Continued from the preceding page.

No.

Item

Appearance No marking defects

Specifications

Capacitance

Change

Char.

X7R

SL

Capacitance Change

Within T15%

Within T2.5% or T0.25pF

(Whichever is larger)

D.F.

16

Temperature

Cycle

Q

I.R.

Char.

X7R

SL

Specification

D.F.V0.05

QU400+20C*2 (CF30pF)

QU1000

(CU30pF)

More than 3,000MΩ

Test Method

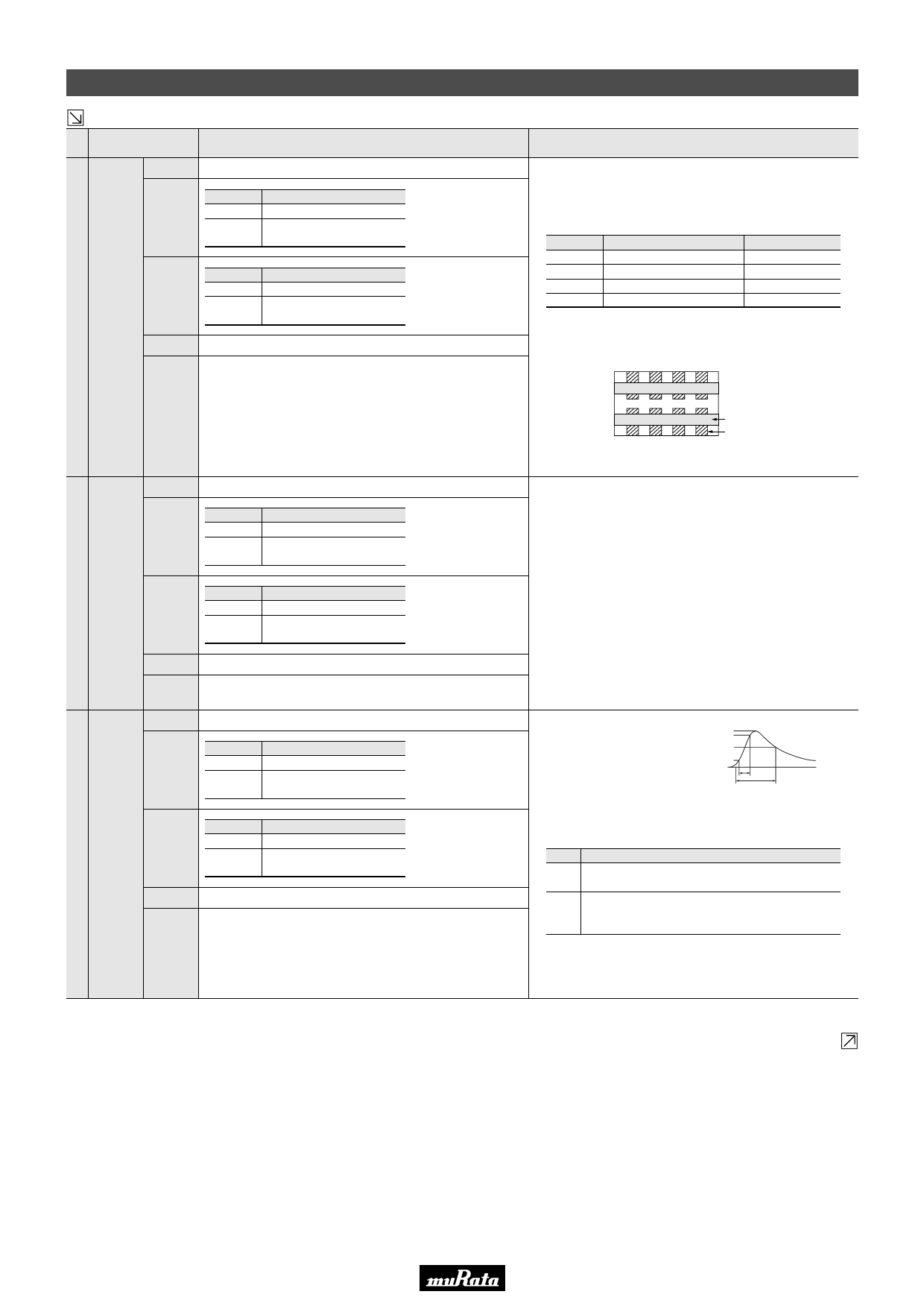

Fix the capacitor to the supporting jig (glass epoxy board) shown

in Fig. 4 using a eutectic solder.

Perform the 5 cycles according to the 4 heat treatments listed in

the following table.

Let sit for 24T2 hrs. at *1room condition, then measure.

Step

Temperature (D)

Time (min.)

1

Min. Operating Temp.T3

2

Room Temp.

3

Max. Operating Temp.T2

4

Room Temp.

30T3

2 to 3

30T3

2 to 3

#Pretreatment for X7R char.

Perform

a

heat

treatment

at

150

W00

Y10

D

for

60T5

min.

and

then

let sit for 24T2 hrs. at *1room condition.

Dielectric

Strength In accordance with item No.4

Appearance No marking defects

Glass Epoxy Board

Fig. 4

Solder resist

Cu

Capacitance

Change

Humidity

17 (Steady

State) D.F.

Q

Char.

X7R

SL

Capacitance Change

Within T15%

Within T5.0% or T0.5pF

(Whichever is larger)

Char.

X7R

SL

Specification

D.F.V0.05

QU275+5/2C*2 (CF30pF)

QU350

(CU30pF)

Let the capacitor sit at 40T2D and relative humidity of 90 to 95%

for 500T12 hrs.

Remove and let sit for 24T2 hrs. at *1room condition, then

measure.

#Pretreatment for X7R char.

Perform

a

heat

treatment

at

150

W00

Y10

D

for

60T5

min.

and

then

let sit for 24T2 hrs. at *1room condition.

I.R.

More than 3,000MΩ

Dielectric

Strength

In accordance with item No.4

18 Life

Appearance No marking defects

Capacitance

Change

Char.

X7R

SL

Capacitance Change

Within T20%

Within T3.0% or T0.3pF

(Whichever is larger)

Char.

Specification

D.F.

X7R

D.F.V0.05

Q

QU275+5/2C*2 (CF30pF)

SL

QU350

(CU30pF)

I.R.

More than 3,000MΩ

Impulse Voltage

Each individual capacitor should

be subjected to a 2.5kV (Type

GC/GF : 5kV) Impulses (the

voltage value means zero to

peak) for three times. Then the

capacitors are applied to life test.

100 (%)

90

50

30

0

T

T2

T1=1.2µs=1.67T

T2=50µs

t

Apply

voltage

as

Table

for

1,000

hrs.

at

125

W2

Y0

D,

relative

humidity 50% max.

Type

Applied voltage

GB

AC312.5V (r.m.s.), except that once each hour the

voltage is increased to AC1,000V (r.m.s.) for 0.1 sec.

GC

GD

AC425V (r.m.s.), except that once each hour the

voltage is increased to AC1,000V (r.m.s.) for 0.1 sec.

GF

Dielectric

Strength

In accordance with item No.4

Let sit for 24T2 hrs. at *1room condition, then measure.

#Pretreatment for X7R char.

Perform

a

heat

treatment

at

150

W00

Y10

D

for

60T5

min.

and

then

let sit for 24T2 hrs. at *1room condition.

*1 "Room condition" Temperature : 15 to 35D, Relative humidity : 45 to 75%, Atmospheric pressure : 86 to 106kPa

*2 "C" expresses nominal capacitance value (pF).

Continued on the following page.

21

127