MK1725 Просмотр технического описания (PDF) - Integrated Circuit Systems

Номер в каталоге

Компоненты Описание

Список матч

MK1725 Datasheet PDF : 6 Pages

| |||

MK1725

Quad Output Spread Spectrum Clock Generator

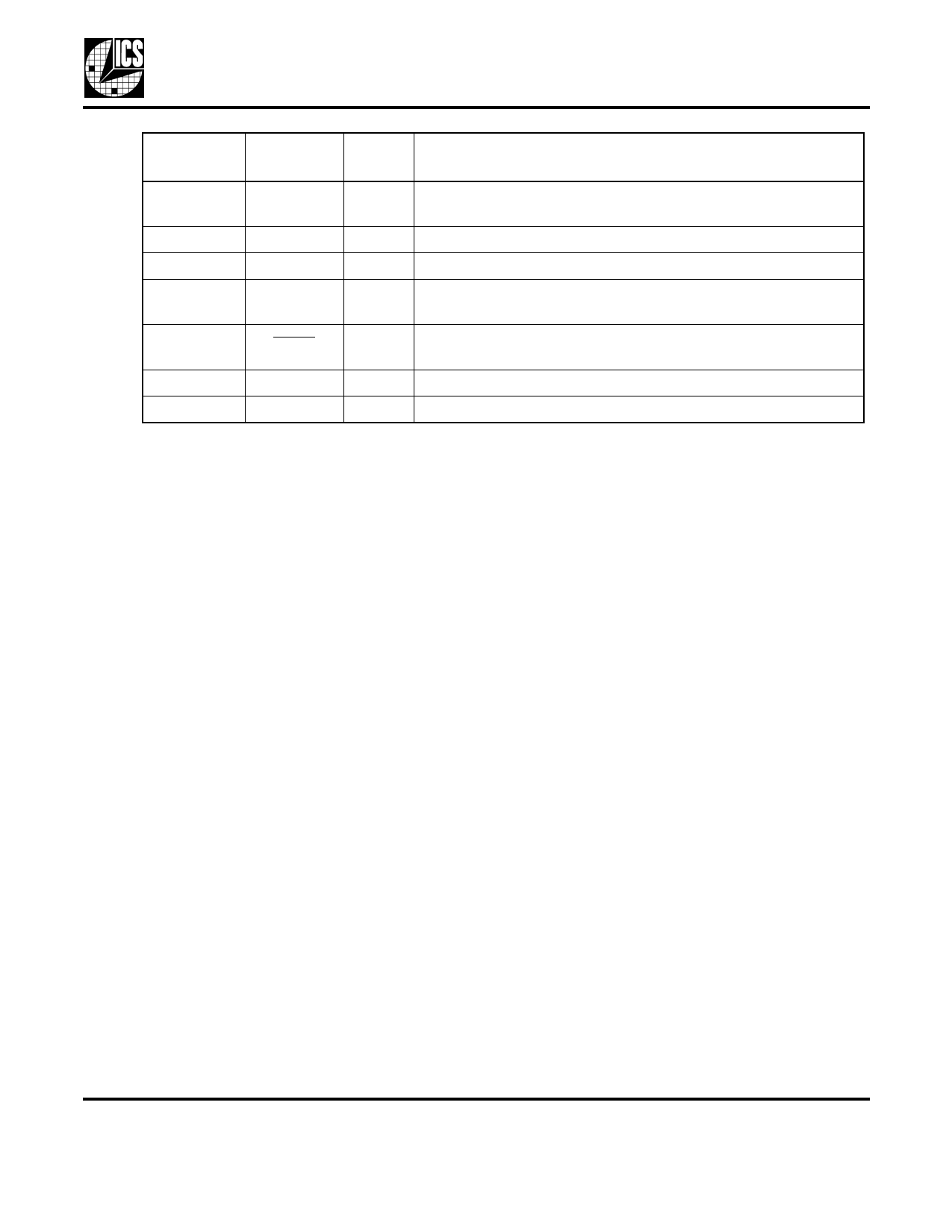

Pin

Number

10

11

12

13

14

15

16

Pin

Name

CLK4

GND

VDD

S2

PDTS

VDD

X2

Pin

Type

Pin Description

Output Clock 4 output. Frequency and spread amount are determined

by table above. Weak internal pull-down when tri-state.

Power Connect to ground.

Power Connect to +3.3V.

Input Select pin 2. Determines frequency and spread amount on

output clocks as per table above. Internal pull-down.

Input

Power Down Tri-state. Powers down entire chip and tri-states

outputs when low. Internal pull-up resistor.

Power Connect to +3.3V.

Input 20MHz-34MHz crystal input. Float for clock input.

External Components

Decoupling Capacitor

As with any high performance mixed-signal IC, the

MK1725 must be isolated from system power supply

noise to perform optimally.

A decoupling capacitor of 0.01µF must be connected

between each VDD and the PCB ground plane.

Series Termination Resistor

Clock output traces over one inch should use series

termination. To series terminate a 50Ω trace (a

commonly used trace impedance), place a 33Ω resistor

in series with the clock line, as close to the clock output

pin as possible. The nominal impedance of the clock

output is 20Ω.

Crystal Load Capacitors

The device crystal connections should include pads for

small capacitors from X1 to ground and from X2 to

ground. These capacitors are used to adjust the stray

capacitance of the board to match the nominally

required crystal load capacitance. Because load

capacitance can only be increased in this trimming

process, it is important to keep stray capacitance to a

minimum by using very short PCB traces (and no vias)

been the crystal and device. Crystal capacitors must be

connected from each of the pins X1 and X2 to ground.

The value (in pF) of these crystal caps should equal

(CL -6)*2. In this equation, CL= crystal load capacitance

in pF. Example: For a crystal with an 18 pF load

capacitance, each crystal capacitor would be 24 pF

[(18-6) x 2] = 24.

PCB Layout Recommendations

For optimum device performance and lowest output

phase noise, the following guidelines should be

observed.

1) The 0.01µF decoupling capacitors should be

mounted on the component side of the board as close

to the VDD pin as possible. No vias should be used

between the decoupling capacitors and VDD pins. The

PCB trace to VDD pins should be kept as short as

possible, as should the PCB trace to the ground via.

2) The external crystal should be mounted just next to

the device with short traces. The X1 and X2 traces

should not be routed next to each other with minimum

spaces, instead they should be separated and away

from other traces.

3) To minimize EMI the 33Ω series termination resistor

(if needed) should be placed close to the clock outputs.

4) An optimum layout is one with all components on the

same side of the board, minimizing vias through other

signal layers. Other signal traces should be routed

away from the MK1725. This includes signal traces just

underneath the device, or on layers adjacent to the

ground plane layer used by the device.

MDS 1725 C

3

Revision 021605

Integrated Circuit Systems ● 525 Race Street, San Jose, CA 95126 ● tel (408) 297-1201 ●www.icst.com