LT3029 Просмотр технического описания (PDF) - Linear Technology

Номер в каталоге

Компоненты Описание

Список матч

LT3029 Datasheet PDF : 20 Pages

| |||

LT3029

APPLICATIONS INFORMATION

Exercise care even when using X5R and X7R capacitors;

the X5R and X7R codes only specify operating temperature

range and maximum capacitance change over temperature.

Capacitance change due to DC bias (voltage coefficient)

with X5R and X7R capacitors is better than with Y5V and

Z5U capacitors, but can still be significant enough to drop

capacitor values below appropriate levels. Capacitor DC

bias characteristics tend to improve as case size increases.

Linear Technology recommends verifying expected versus

actual capacitance values at operating voltage in situ for

an application.

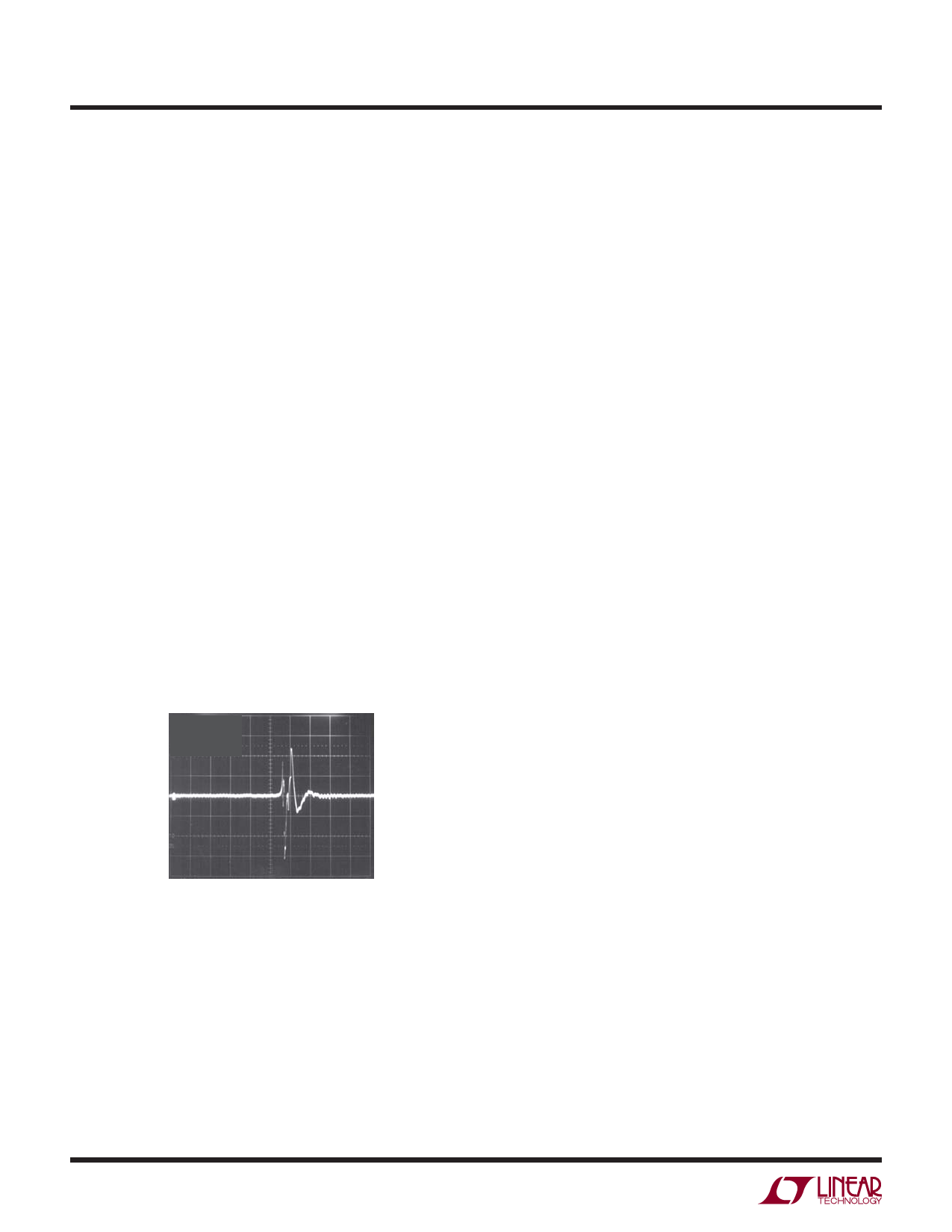

Voltage and temperature coefficients are not the only

sources of problems. Some ceramic capacitors have a

piezoelectric response. A piezoelectric device generates

voltage across its terminals due to mechanical stress,

similar to the way a piezoelectric accelerometer or micro-

phone works. For a ceramic capacitor, the stress can be

induced by vibrations in the system or thermal transients.

The resulting voltages produced can cause appreciable

amounts of noise, especially when a ceramic capacitor is

used for noise bypassing. A ceramic capacitor produced

Figure 4’s trace in response to light tapping from a pencil.

Similar vibration induced behavior can masquerade as

increased output voltage noise.

COUT = 10μF

CBYP = 0.01μF

ILOAD = 500mA

VOUT

500μV/DIV

100ms/DIV

3029 F04

Figure 4. Noise Resulting from Tapping on a Ceramic Capacitor

Thermal Considerations

The LT3029’s power handling capability limits the maximum

rated junction temperature (125°C, LT3029E/LT3029I/

LT3029MP or 150°C, LT3029H). Two components comprise

the power dissipated by each channel:

1. Output current multiplied by the input/output voltage

differential: (IOUT)(VIN – VOUT), and

2. GND pin current multiplied by the input voltage:

(IGND)(VIN).

Ground pin current is found by examining the GND Pin

Current curves in the Typical Performance Characteristics

section.

Power dissipation for each channel equals the sum of the

two components listed above. Total power dissipation for

the LT3029 equals the sum of the power dissipated by

each channel.

The LT3029’s internal thermal shutdown circuitry protects

both channels of the device if either channel experiences

an overload or fault condition. Activation of the thermal

shutdown circuitry turns both channels off. If the overload

or fault condition is removed, both outputs are allowed

to turn back on. For continuous normal conditions, do

not exceed the maximum junction temperature rating of

125°C (LT3029E/LT3029I/LT3029MP) or 150°C (LT3029H).

Carefully consider all sources of thermal resistance from

junction-to-ambient, including additional heat sources

mounted in proximity to the LT3029. For surface mount

devices, use the heat spreading capabilities of the PC board

and its copper traces to accomplish heat sinking. Copper

board stiffeners and plated through-holes can also spread

the heat generated by power devices.

The following tables list thermal resistance as a function

of copper area in a fixed board size. All measurements

were taken in still air on a four-layer FR-4 board with 1oz

solid internal planes, and 2oz external trace planes with a

total board thickness of 1.6mm. For further information

on thermal resistance and using thermal information, refer

to JEDEC standard JESD51, notably JESD51-12.

3029fa

14